Luyckx news

02.06.2023

BLOG: Digidate with Luyckx

The Luyckx tagline ‘Minds & Machinery’ gives it away a bit, of course. The company located in Brecht combines smart minds with the distribution and service of high-quality machines. Digitalisation is then never far away…

We put our microphone in front of the most ‘digi-wise’ minds at Luyckx: Mathias (with Bluetooth headset invariably behind his ear), Robbe (only 22 years old) and Tinne (with the digi-overview).

How digital is Luyckx?

Tinne: Very digital! Digitalisation is really interwoven throughout the entire company. We employ digitalisation wherever it can improve our efficiency. This is always in function of our customer.

Can you give an example?

Tinne: For example, we use an app in which our service technicians fill in their intervention data. We’ve fully digitalised the previous paper work order. That ensures more oversight, fewer mistakes and transparency. Our technicians fill in their digital work order onsite and we can read along internally and take action proactively at the same time. In addition, he can send an order confirmation to the customer immediately after the job. The customer knows at once that the machine has been repaired and exactly what has been done. That provides enormous time savings and efficiency.

Where else are you digitalising?

Tinne: We have our webshop, MyMachine (tracking of machines), and also a couple of internal IT-trainers who give our people ongoing training and constantly examine our processes. They look for opportunities where digitalisation can improve our processes. That ranges from very small hands-on things like using a shortcut to cut and paste to advanced digitalisation in company processes.

Digitalisation and personal contact go hand in hand

Is digitalisation really part of your strategy?

Tinne: Absolutely. The Luyckx family wants to make the company as ‘digi-wise’ as possible. Chantal Luyckx is the driving force behind this, literally and figuratively. And Jos and Paula too (despite their age) completely agree with the need for digitalisation. They walk fast, but they think fast too (everyone laughs).

How do customers feel about all that digitalisation?

Tinne: Digitalisation should make things easier, not harder. Customers can still decide for themselves how they contact us. They can do it 24 hours a day, so to speak, through our webshop, but they can also still do it by telephone or via a personal appointment. One doesn’t rule out the other. Digitalisation and personal contact go hand in hand, really. In fact, digitalisation ensures that we can become even more involved in personal contact and service, because it saves time for all parties.

Do all your customers support that digital approach?

Tinne: It’s our intention of course to make the digitalisation of our services as user-friendly as possible. So we help and support our customers when that’s needed. But when a customer prefers to do things the old-fashioned way, we also accommodate them. Digitalisation is a journey we’re taking together. We adapt, at our customers’ pace.

Mathias: In fact there are only advantages to be gained from digitalisation. It makes things easier and less expensive for the customer, and we can all concern ourselves more with our core task: helping our customers as much as possible.

Digitalisation has also become essential in the machine themselves.

Mathias: Right,

that’s an evolution that keeps going. There are more and more electronics in

machines. But those machines will also get many more functionalities because of

this. There are brands that are completely abandoning hydraulic controls and

decisively choosing electronically controlled machines.

How do electronics make a machine better?

Mathias: Machine performance is becoming more and more accurate and precise because of it. You can also capture and analyse data thanks to digitalisation. That gives enormous insight into the efficiency of a machine. In addition, possible problems with a machine are immediately traceable using sensors. It makes service of a machine more transparent because you can read all the parameters of the machine remotely. In other words, you can detect the problem anywhere in the world via a computer.

MyMachine, a digital helicopter view

How does that work in practice?

Mathias: You can see it this way: you have the machine in the field, and then you have the technician remotely looking at a digital twin of that same machine at the same time.

That brings us to MyMachine.

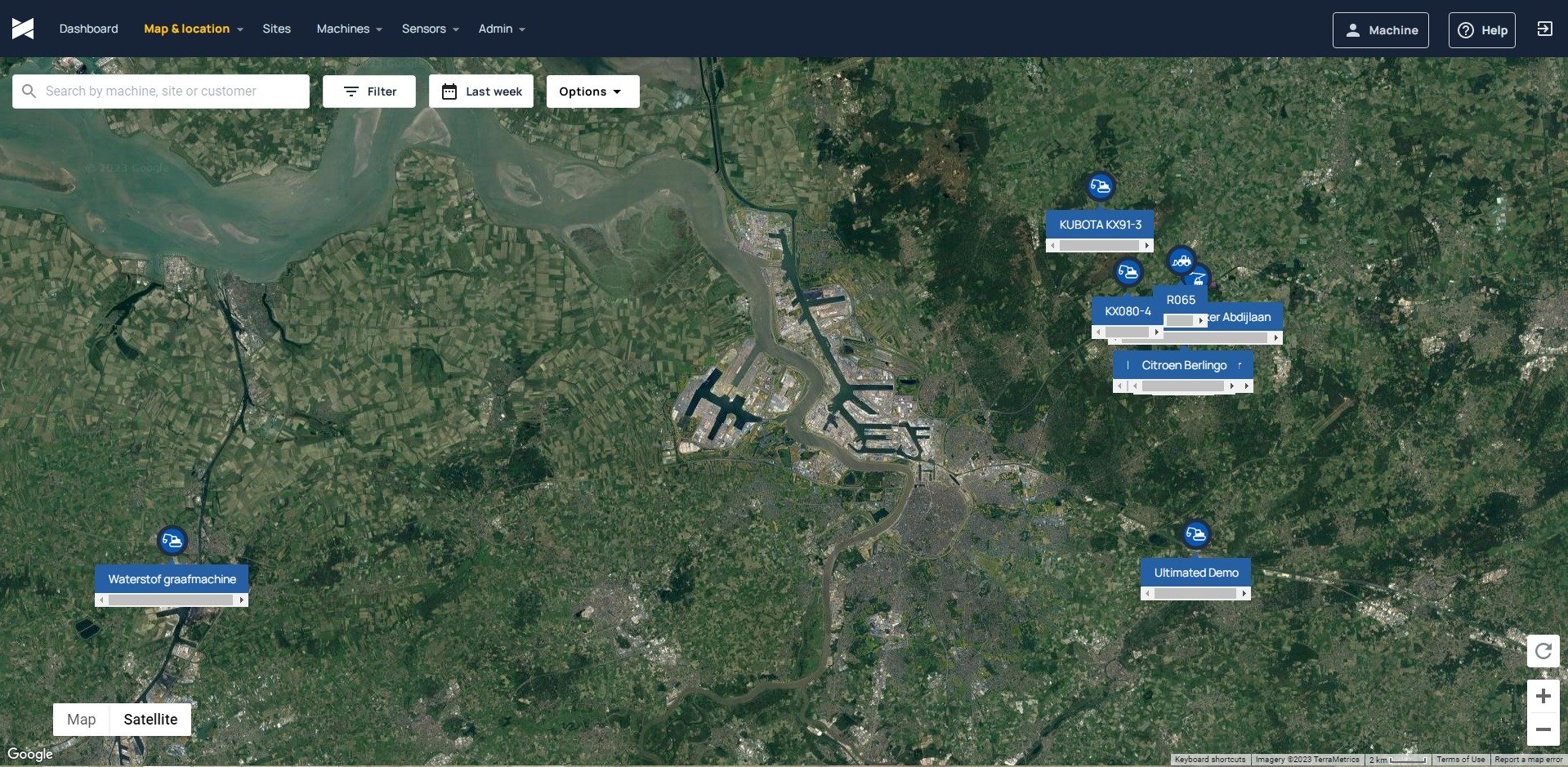

Robbe: So it does. MyMachine is an online platform with which we can read out all the data using a sensor in the machine. You can see where the machine is located and what it’s doing in real time.

Mathias: In addition, MyMachine maps out your whole fleet, regardless of the brands. You can monitor your so-called mixed fleet at a glance, remotely. It gives you an overarching helicopter view of your fleet. So we make things as easy as possible for our customers by means of a total package in which we assemble all the data.

A wealth of information

What is the advantage for the customer?

Mathias: That digital overview offers a wealth of information. Maybe you have rented a machine somewhere that has been barely operational for some time, while you can use a machine of your own. So you can save unnecessary rent.

Tinne: On large sites you can view the movements of your machines. With that information you can lay out your site more efficiently and save large quantities of fuel and CO2 emissions.

Mathias: You can literally monitor the routes of the trucks and see how many tons they have moved in a day. You can compare tonnages to fuel consumption so that you get better insight into your return.

Robbe: We also see, for example, how many hours the machine is operating, when it’s actually working and when it’s idling (inactive). That insight into data can be very beneficial to the owner. So again you can save a significant amount of fuel. We see that when you can save five minutes per day of idling, you have already recouped the investment in the MyMachine platform.

How do you know that so precisely?

Robbe: I did my thesis on it (laughs).

You need to explain that a bit.

Robbe: Well, first I had a summer job here, and then I also did my traineeship in after-sales service. It was a logical step for me to do my thesis on MyMachine. The digital platform really appealed to me immediately. I found it an enormously interesting subject. And voilà, now I work here.

How long have you worked at Luyckx?

Robbe: Just three months.

And now you're already responsible for MyMachine. That's impressive for such a young fellow...

Robbe: Thank you, I’m very glad that I was given this opportunity.

Tinne: I think that that’s also typical Luyckx. We don’t look at age here, but at competence and motivation.

Mathias: That’s how I feel too. It’s also a highly varied job. We install the sensors, do the customer contact, follow up behind the computer, etc. And we’re more than just a dealer of machines. We support our customers with additional services like MyMachine that make life easier for them.

To measure is to know

How do customers react to MyMachine?

Robbe: Customers who get started with it are very enthusiastic about it. Once it’s in use, they quickly see its advantages.

Mathias: We recently contacted a Hitachi customer whose machines are equipped with oil sensors. The sensors indicated that the oil urgently needed to be replaced. We prevent significant costs with that constant 24/7 monitoring. But we can also analyse machines remotely and use software to solve certain problems.

Tinne: To measure is to know. You can simply manage your fleet better, and it reduces the total cost of ownership.

Mathias: Yes, your machines go for maintenance at the right times, they operate more efficiently with as little idling as possible, and you know where they’re located. By the way, we were able to clear up a theft of a machine this way.

Robbe: At the moment we’re also conducting tests with remote access control. Every operator gets a code or a badge that allows him and only him to access a certain machine.For example, we can remotely set the time period in which the operator can/may operate a certain machine.

Are the machines becoming more complex too, so that customers also need more high-quality support?

Mathias: That’s right. We’re also constantly learning and are always up to date on the newest developments. You can’t keep track of all that as an end customer.

Tinne: I think you can say that at Luyckx we embrace all aspects of digitalisation.

Why in fact did you decide to develop MyMachine yourself?

Mathias: We were getting more and more requests from our customers to digitalise. It was also a logical step for Luyckx. We were already responsible for sales, maintenance and service. Digital management is the final element of our service-oriented approach. We naturally know the machines through and through, and so were perhaps the party in the best position to produce such a platform.

Robbe: We’ve also made it as user-friendly as possible. Now we provide the sensors by default on every machine, so you can call on MyMachine whenever you want.

Tinne: The combination of that digital monitoring and our technical expertise in practice is our strength.

Have you also had to retrain your technicians?

Mathias: That has been a routine process. The use of software has been going on for years, of course. Our people have always evolved along with it.

Tinne: I think that’s also somewhat the mindset of everyone who works at Luyckx. Everyone here wants to keep learning too and keep up with the latest new developments. That way we keep each other up to speed.

Where are we headed?

How do you see the future with regard to digitalisation? Where is it headed?

Mathias: It’s moving at lightning speed. Furthermore you clearly see an evolution towards more and more connected. Everything and everyone is connected. Excavators are becoming more and more robots in which the machine is becoming more and more accurate.

Tinne: That brings us to our joint venture with Ultimated.

Mathias: Right, they equip the machines with digging control systems and machine control. With that the excavator is able to excavate down to the centimeter, which can have an enormous impact in large areas.

Tinne: Tractors are being equipped with them too, so that you can mark out your field much better, sow more efficiently, you name it.

Robbe: You can set up everything perfectly; your field, your work area, your seeder, etc., so that you will never have overlap. The tractor also drives itself in large part. Technology can really be a gamechanger.

Is the operator then becoming unnecessary in the long term?

Mathias: No, I don’t think so. His or her task will keep changing and evolving. The human supervision will always remain. Data entry, customising the machine, will then obviously become a core task.

Tinne: The human component will continue to make the difference, I think. The combination of experience, expertise and technology is the great strength.

Mathias: Well-trained operators are already a bottleneck now. By equipping machines with technology, you can build some experience into the machine, so that it becomes easier to have a new operator begin. When we deliver a new machine to a customer he gets a comprehensive explanation in any case, but we also offer courses.

#Spirit

Why do you like this job so much? And why does that digital aspect appeal to you so?

Robbe: Speaking for myself, I’ve been raised with digitalisation, of course. And as a little kid I was already occupied with perusing tractor manuals. I’ve always been fascinated by big machines. If you can then combine those two, that’s ideal. I also just like to keep up with things. And you have to.

Mathias: Technology has always appealed to me in general. I too was busy drawing cars and machines in detail since childhood (laughs). Here at Luyckx I can really let myself go in that respect. I was also there at the inception of MyMachine, and am involved in the hydrogen initiative too. When we start a new project, I’m involved too. Then they say, “Mathias, this is the problem, solve it.” I enjoy that.

Tinne: Always wanting to do things better. We all want to move forward here. That drive is very inspirational.